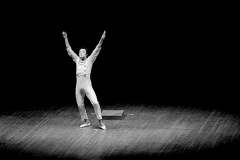

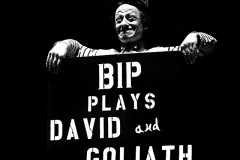

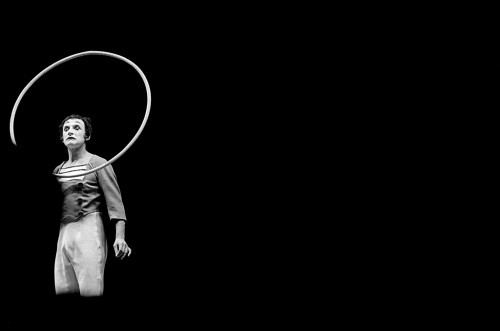

One of the advantages of working for The Ohio University Post and The Athens Messenger was access to press credentials to cover some of the best performers of the time. I was fortunate enough to photograph Marcel Marceau when he performed at Memorial Auditorium on February 16, 1968 (if the negative sleeve is right).

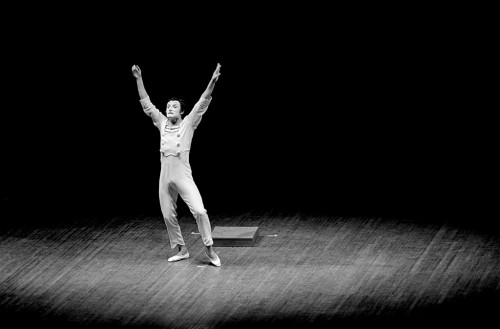

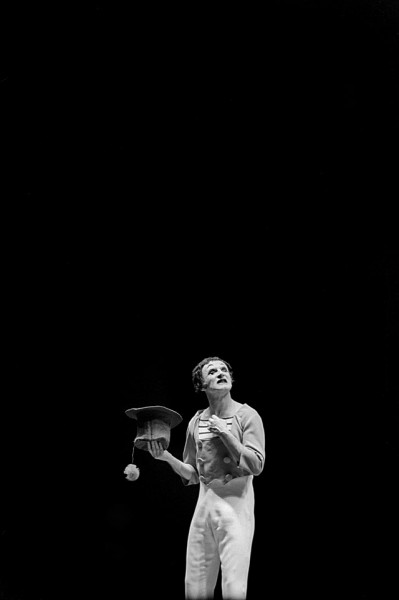

One of the advantages of working for The Ohio University Post and The Athens Messenger was access to press credentials to cover some of the best performers of the time. I was fortunate enough to photograph Marcel Marceau when he performed at Memorial Auditorium on February 16, 1968 (if the negative sleeve is right).

Never saw anyone do more with less

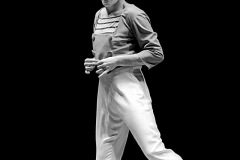

I was impressed with how little it took Simon and Garfunkel to put on their concert, but Marceau required even less equipment. All he needed was a stage and a spotlight to hold an audience spellbound.

I was impressed with how little it took Simon and Garfunkel to put on their concert, but Marceau required even less equipment. All he needed was a stage and a spotlight to hold an audience spellbound.

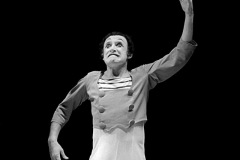

Show was technically challenging

This was a performance where it really paid off to show up early enough to take an incident light reading on the stage before the show began. If I had tried to use a standard reflective light meter, it would have been fooled by the ocean of blackness surrounding Marceau. An incident light meter measures the light falling onto the subject rather than the light reflecting off the subject. That was my preferred method of metering when I could use it. Luckily, I was able to get the spot operator to fire it up long enough for me to get a reading.

This was a performance where it really paid off to show up early enough to take an incident light reading on the stage before the show began. If I had tried to use a standard reflective light meter, it would have been fooled by the ocean of blackness surrounding Marceau. An incident light meter measures the light falling onto the subject rather than the light reflecting off the subject. That was my preferred method of metering when I could use it. Luckily, I was able to get the spot operator to fire it up long enough for me to get a reading.

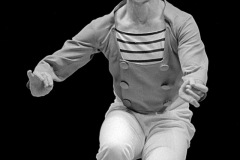

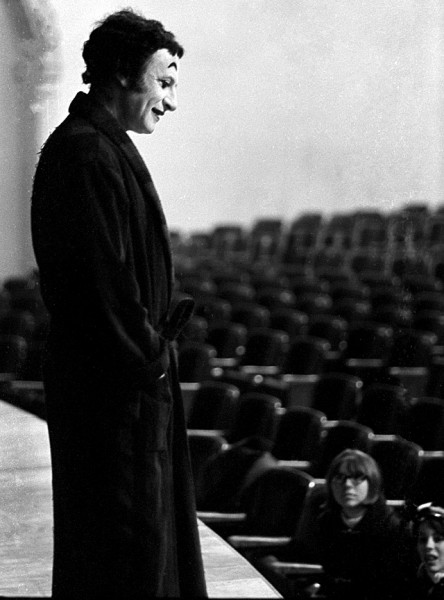

I’m not sure what’s happening

I don’t know if this was taken during a rehearsal, before the show or when. The house was packed for the actual performance, but there was only a handful of people around when I shot this.

I don’t know if this was taken during a rehearsal, before the show or when. The house was packed for the actual performance, but there was only a handful of people around when I shot this.

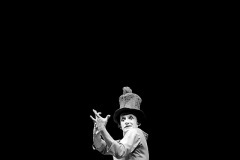

“White ink drawings on black backgrounds”

Marceau once said, “I have designed my style pantomimes as white ink drawings on black backgrounds, so that man’s destiny appears as a thread lost in an endless labyrinth. I have tried to shed some gleams of light on the shadow of man startled by his anguish.”

Marceau once said, “I have designed my style pantomimes as white ink drawings on black backgrounds, so that man’s destiny appears as a thread lost in an endless labyrinth. I have tried to shed some gleams of light on the shadow of man startled by his anguish.”

When I looked at these frames, I knew exactly what he was talking about. I’ve never seen anyone who used black space more effectively.

Father killed at Auschwitz

A biography on the IMDb website said that Marceau was born Marcel Mangel on March 22, 1923, in Strasbourg, Alsace, France. At age 5, he was entranced when his mother took him to see a Charlie Chaplin movie; he decided to become a mime. At the beginning of World War II, he had to hide his Jewish origin and changed his name to Marceau. His father was deported to Auschwitz, where he was killed in 1944.

A biography on the IMDb website said that Marceau was born Marcel Mangel on March 22, 1923, in Strasbourg, Alsace, France. At age 5, he was entranced when his mother took him to see a Charlie Chaplin movie; he decided to become a mime. At the beginning of World War II, he had to hide his Jewish origin and changed his name to Marceau. His father was deported to Auschwitz, where he was killed in 1944.

Marceau and his brother, Alain, were in the French underground and helped children escape to neutral Switzerland. He later served as interpreter for the Free France Forces under General Charles de Gaulle.

When he died in 2007, Timothy W. Ryback wrote in The New York Times about Marceau’s concern about the fragility of his art. “Unlike novels or plays or operas, which could be printed, recorded, preserved, the art of mime was a transitory and ephemeral art. It existed only in the moment. And, more unsettling still, essentially in one man, Marcel Marceau,” Ryback said.

Photo gallery of Marcel Marceau

I’m glad I had a chance to see the world’s best-known mime. Click on any photo to make it larger, then click on the left or right side to move through the gallery. By the way, while researching this, I saw a link to “Marcel Marceau quotes.” I figured clicking on it would take me to a blank page. Surprisingly enough, Marceau said, among other things, “Never get a mime talking. He won’t stop.”